Specifications:

| Sealing Bar | mm | 270 |

|---|---|---|

| Pump Supplied | mc/h | 6 |

| Optional Pump | mc/h | 8 |

| Busch Pump | mc/h | 6 |

| Bath | mm | 300x325x95+45h |

| Power | kW(HP) | 0,5(0,7) |

| Weight | kg | 34 |

Characteristics:

Chamber machines for medium business users. To vacuum package a wide variety of foods and other materials that suffer from contact with air, to prolong the shelf life. Durable, reliable, fast, easy to use and clean ...

To improve customer service in retail food and catering. A good relationship between price and performance!

♦ Body and 304 stainless steel tank

♦ Plans included filling

♦ Convex lid Methacrylate very sturdy, with locking device

♦ Sealing bar piston up, easy to disassemble for cleaning, without cables flying

♦ Timers and welding time with digital controls

♦ Low voltage controls (24 V)

♦ Machine conforming to EC rules on hygiene and safety

Specifications:

| Sealing Bar | mm | 300 |

|---|---|---|

| Pump Supplied | mc/h | 12 |

| Optional Pump | mc/h | 18 |

| Busch Pump | mc/h | 10 |

| Bath | mm | 310x340x115+45h |

| Power | kW(HP) | 0,6(0,8) |

| Weight | kg | 47 |

Characteristics:

Chamber machines for medium business users. To vacuum package a wide variety of foods and other materials that suffer from contact with air, to prolong the shelf life. Durable, reliable, fast, easy to use and clean ...

To improve customer service in retail food and catering. A good relationship between price and performance!

♦ Body and 304 stainless steel tank

♦ Plans included filling

♦ Convex lid Methacrylate very sturdy, with locking device

♦ Sealing bar piston up, easy to disassemble for cleaning, without cables flying

♦ Timers and welding time with digital controls

♦ Low voltage controls (24 V)

♦ Machine conforming to EC rules on hygiene and safety

Specifications:

| Sealing Bar | mm | 350 |

|---|---|---|

| Pump Supplied | mc/h | 12 |

| Optional Pump | mc/h | 18 |

| Busch Pump | mc/h | 10 |

| Bath | mm | 360x405x115+52h |

| Power | kW(HP) | 0,6(0,8) |

| Weight | kg | 55 |

Characteristics:

Chamber machines for medium business users. To vacuum package a wide variety of foods and other materials that suffer from contact with air, to prolong the shelf life. Durable, reliable, fast, easy to use and clean ...

To improve customer service in retail food and catering. A good relationship between price and performance!

♦ Body and 304 stainless steel tank

♦ Plans included filling

♦ Convex lid Methacrylate very sturdy, with locking device

♦ Sealing bar piston up, easy to disassemble for cleaning, without cables flying

♦ Timers and welding time with digital controls

♦ Low voltage controls (24 V)

♦ Machine conforming to EC rules on hygiene and safety

Specifications:

| Sealing Bar | mm | 410 |

|---|---|---|

| Pump Supplied | mc/h | 18 |

| Optional Pump | mc/h | 25 |

| Busch Pump | mc/h | 20 |

| Bath | mm | 420x470x120+75h |

| Power | kW(HP) | 0,75(1) |

| Weight | kg | 80 |

Characteristics:

Chamber machines for medium business users. Durable, reliable, fast, easy to use and clean ...

To improve customer service in retail food and catering. A good relationship between price and performance!

PACK 16B: Bench

♦ Body and 304 stainless steel tank

♦ Plans included filling

♦ Convex lid Methacrylate very sturdy, with locking device

♦ Sealing bar piston up, easy to disassemble for cleaning, without cables flying

♦ Timers and welding time with digital controls

♦ Low voltage controls (24 V)

♦ Machine conforming to EC rules on hygiene and safety

Specifications:

| Sealing Bar | mm | 470 |

|---|---|---|

| Pump Supplied | mc/h | 18 |

| Optional Pump | mc/h | 25 |

| Busch Pump | mc/h | 20 |

| Bath | mm | 480x470x120+85h |

| Power | kW(HP) | 0,75(1) |

| Weight | kg | 90 |

Characteristics:

Chamber machines for medium business users. Durable, reliable, fast, easy to use and clean ...

To improve customer service in retail food and catering. A good relationship between price and performance!

PACK 20B: Bench

♦ Body and 304 stainless steel tank

♦ Plans included filling

♦ Convex lid Methacrylate very sturdy, with locking device

♦ Sealing bar piston up, easy to disassemble for cleaning, without cables flying

♦ Timers and welding time with digital controls

♦ Low voltage controls (24 V)

♦ Machine conforming to EC rules on hygiene and safety

Specifications:

| 2 Sealing Bars | mm | 500+500 |

|---|---|---|

| Pump Supplied | mc/h | 25 |

| Optional Pump | mc/h | 40 |

| Busch Pump optional | mc/h | 25 |

| Bath | mm | 510x500x120+95h |

| Power | kW(HP) | 1,1(1,3) |

| Weight | kg | 110 |

Characteristics:

Chamber machines for medium business users. Durable, reliable, fast, easy to use and clean ...

To improve customer service in retail food and catering. A good relationship between price and performance!

PACK 25B: roundup

♦ Body and 304 stainless steel tank

♦ Plans included filling

♦ Convex lid Methacrylate very sturdy, with locking device

♦ Sealing bar piston up, easy to disassemble for cleaning, without cables flying

♦ Timers and welding time with digital controls

♦ Low voltage controls (24 V)

♦ Machine conforming to EC rules on hygiene and safety

♦ Two parallel sealing bars

Specifications:

| Sealing Bar | mm | 410 |

|---|---|---|

| Vacuum Pump | mc/h | 16 |

| Bath | mm | 420x450x120+80h |

| Engine Power | kW(HP) | 0,7(0,94) |

| Weight | kg | 62 |

Description:

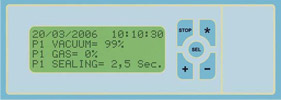

The structure and the tank are 304 stainless steel, domed lid is thicker and is very sturdy will not bend. The system of sealing the bags with scrap cutting welding ensures a strong and uniform and maximum resistance to internal stresses and temperature variations. The size of the bars have been studied in relation to the size of most commonly used packages and methods observed in the many years of work and expertise to ensure optimum utilization of machines. All machines are equipped PACK range of programs that allow you to store the welding time, the percentage of empty or gas and can choose from 9 extra empty.

The programming is simple, fast, wizard, to configure the machine according to their specific needs. The cycle is completely automatic, but can also be adjusted manually. All machines in our range are equipped with EVC (Electronic Vacuum Control), which, by means of a sophisticated and reliable digital control, measures the degree of vacuum suction and blocks when they reached the programmed conditions, without a margin of error for maximum packing efficiency and the best results. The vacuum pumps are powerful, highly reliable and require little maintenance. They are built with special materials and recirculating oil lubricated. They work at low levels of friction for increased durability. You can quickly reach a vacuum level equal to 99.8% of atmospheric pressure. The cleaning machine is fast and easy: all stainless steel or smooth surfaces, rods removed without wires, edges and rounded corners, no dirt traps, ...

Specifications:

| Sealing Bar | mm | 500 |

|---|---|---|

| Vacuum Pump | mc/h | 20 |

| Bath | mm | 510x490x120+90h |

| Engine Power | kW(HP) | 0,8(1,07) |

| Weight | kg | 90 |

Description:

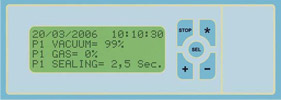

The structure and the tank are 304 stainless steel, domed lid is thicker and is very sturdy will not bend. The system of sealing the bags with scrap cutting welding ensures a strong and uniform and maximum resistance to internal stresses and temperature variations. The size of the bars have been studied in relation to the size of most commonly used packages and methods observed in the many years of work and expertise to ensure optimum utilization of machines. All machines are equipped PACK range of programs that allow you to store the welding time, the percentage of empty or gas and can choose from 9 extra empty.

The programming is simple, fast, wizard, to configure the machine according to their specific needs. The cycle is completely automatic, but can also be adjusted manually. All machines in our range are equipped with EVC (Electronic Vacuum Control), which, by means of a sophisticated and reliable digital control, measures the degree of vacuum suction and blocks when they reached the programmed conditions, without a margin of error for maximum packing efficiency and the best results. The vacuum pumps are powerful, highly reliable and require little maintenance. They are built with special materials and recirculating oil lubricated. They work at low levels of friction for increased durability. You can quickly reach a vacuum level equal to 99.8% of atmospheric pressure. The cleaning machine is fast and easy: all stainless steel or smooth surfaces, rods removed without wires, edges and rounded corners, no dirt traps, ...

Specifications:

| 2 sealing bars | mm | 520+520 |

|---|---|---|

| Vacuum Pump | mc/h | 40 |

| Bath | mm | 630x530x120+100h |

| Engine Power | kW(HP) | 1,3(1,74) |

| Weight | kg | 155 |

Description:

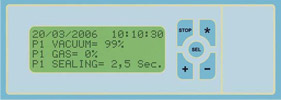

The structure and the tank are 304 stainless steel, domed lid is thicker and is very sturdy will not bend. The system of sealing the bags with scrap cutting welding ensures a strong and uniform and maximum resistance to internal stresses and temperature variations. The size of the bars have been studied in relation to the size of most commonly used packages and methods observed in the many years of work and expertise to ensure optimum utilization of machines. All machines are equipped PACK range of programs that allow you to store the welding time, the percentage of empty or gas and can choose from 9 extra empty.

The programming is simple, fast, wizard, to configure the machine according to their specific needs. The cycle is completely automatic, but can also be adjusted manually. All machines in our range are equipped with EVC (Electronic Vacuum Control), which, by means of a sophisticated and reliable digital control, measures the degree of vacuum suction and blocks when they reached the programmed conditions, without a margin of error for maximum packing efficiency and the best results. The vacuum pumps are powerful, highly reliable and require little maintenance. They are built with special materials and recirculating oil lubricated. They work at low levels of friction for increased durability. You can quickly reach a vacuum level equal to 99.8% of atmospheric pressure. The cleaning machine is fast and easy: all stainless steel or smooth surfaces, rods removed without wires, edges and rounded corners, no dirt traps, ...

Specifications:

| 2 sealing bars | mm | 540+540 |

|---|---|---|

| Vacuum Pump | mc/h | 63 |

| Bath | mm | 620x550x120+100h |

| Engine Power | kW(HP) | 1,8(2,41) |

| Weight | kg | 175 |

Description:

The structure and the tank are 304 stainless steel, domed lid is thicker and is very sturdy will not bend. The system of sealing the bags with scrap cutting welding ensures a strong and uniform and maximum resistance to internal stresses and temperature variations. The size of the bars have been studied in relation to the size of most commonly used packages and methods observed in the many years of work and expertise to ensure optimum utilization of machines. All machines are equipped PACK range of programs that allow you to store the welding time, the percentage of empty or gas and can choose from 9 extra empty.

The programming is simple, fast, wizard, to configure the machine according to their specific needs. The cycle is completely automatic, but can also be adjusted manually. All machines in our range are equipped with EVC (Electronic Vacuum Control), which, by means of a sophisticated and reliable digital control, measures the degree of vacuum suction and blocks when they reached the programmed conditions, without a margin of error for maximum packing efficiency and the best results. The vacuum pumps are powerful, highly reliable and require little maintenance. They are built with special materials and recirculating oil lubricated. They work at low levels of friction for increased durability. You can quickly reach a vacuum level equal to 99.8% of atmospheric pressure. The cleaning machine is fast and easy: all stainless steel or smooth surfaces, rods removed without wires, edges and rounded corners, no dirt traps, ...

Specifications:

| 2 sealing bars | mm | 540+750 |

|---|---|---|

| Vacuum Pump | mc/h | 63 |

| Bath | mm | 820x600x120+100h |

| Engine Power | kW(HP) | 1,8(2,41) |

| Weight | kg | 195 |

Description:

The structure and the tank are 304 stainless steel, domed lid is thicker and is very sturdy will not bend. The system of sealing the bags with scrap cutting welding ensures a strong and uniform and maximum resistance to internal stresses and temperature variations. The size of the bars have been studied in relation to the size of most commonly used packages and methods observed in the many years of work and expertise to ensure optimum utilization of machines. All machines are equipped PACK range of programs that allow you to store the welding time, the percentage of empty or gas and can choose from 9 extra empty.

The programming is simple, fast, wizard, to configure the machine according to their specific needs. The cycle is completely automatic, but can also be adjusted manually. All machines in our range are equipped with EVC (Electronic Vacuum Control), which, by means of a sophisticated and reliable digital control, measures the degree of vacuum suction and blocks when they reached the programmed conditions, without a margin of error for maximum packing efficiency and the best results. The vacuum pumps are powerful, highly reliable and require little maintenance. They are built with special materials and recirculating oil lubricated. They work at low levels of friction for increased durability. You can quickly reach a vacuum level equal to 99.8% of atmospheric pressure. The cleaning machine is fast and easy: all stainless steel or smooth surfaces, rods removed without wires, edges and rounded corners, no dirt traps, ...

Specifications:

| External Dimensions | (WxDxH) | 580x730x1300mm |

|---|---|---|

| Working Height | 850mm | |

| Max Tray Depth | 100mm | |

| Max Film Width | 450mm | |

| Pump Busch | 21 | |

| Power | 1.5kW | (1phase) |

Description:

The Turbovac tray packing machine (TPS) has been designed to pack all food products in a modified atmosphere, suitable in a a semi industrial environment. The TPS combines quality with easy machine operation and maintenance.

One of the unique features of the TPS compact is the ability to change moulds in seconds with little more than a turn of a key.

With a Turbovac TPS compact you can be sure that your packs are secure with an accurate controlled atmosphere and that the presentation is professional and attractive.

Specifications:

| Model | VG 800 LCD |

|---|---|

| Overall dimensions (mm) | 610x600x1100h |

| Workig cycle | automatic |

| Maximum container dimensions | mm 265x325 |

| Vacuum pump | Q= 25 m3/h |

| Voltage | 230 V/50 Hz |

| Installed Power | 1800 W |

| Control Panel | digit Lcd-10 PRG |

Description:

"Termovac" line of two thermosealers is strongly recommended for all those small/medium workrooms interested in vacuum packing their own production in trays. A complete working cycle follows three simple steps:

Placing tray in the specific mould and start vacuum phase

Inert gas injection

Sealing phase: film is hermetically sealed on trays

These three steps are naturally put into execution by the thermosealer itself, which automatically stops at the end of the working cycle only.

Both models are in the latest version, with the brand new pneumatic sealing by a 3BAR piston and specific VACUUM-GAS sensor on the electronic board.

The sealing film cut is made on both sides of the 1/2 GASTRO tray, but both 1/4 GASTRO and 1/8 GASTRO necessarily need the manual intervention by the operator to cut the exceeding films between trays.

Both models are totally made of inox steel and aluminium. Average daily production: from 150 to 300 trays a day.