| MODEL | BGR-300 |

|---|---|

| ø Pulley | 300 |

| A1 | 625 |

| A2 | 790 |

| B | 1.670 |

| C1 | 610 |

| C2 | 745 |

| D | 775 |

| E | 604 |

| F | 900 |

| G | 350 |

| H | 275 |

| I | 322 |

| J | 1485 |

| K | 453 |

| L | 329 |

| Kg. | 155 |

| Cv. III | 3 |

| Blade | 2.500 |

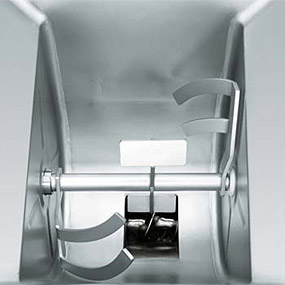

Characteristics:

♦ Bandsaw for the meat and fish industries. Special robustness for large meat processing facilities and easy operating procedure.

♦ The design eases a good integration on the different lines of cutting process.

♦ Robust 18/10 stainless steel construction.

♦ Stainless steel pulleys with double flap.

♦ Automatic process of tension control.

♦ Safety device to stop running blade in 4 seconds.

♦ On-off switch with emergency stop button, IP65.

♦ Safety device when opening door.

♦ No volt release system.

♦ Manufacturing of blade on the right and left hand side.

♦ Easy cleaning with water pressure.

♦ A one piece body construction to ease the better cleaning on a uniform platform.

♦ Detachable cleaners for easy cleaning, without the use of tools.

♦ Scrapers for pulley cleaning purpose on the cutting process.

| MODEL | BGR-360 |

|---|---|

| ø Pulley | 360 |

| A1 | 625 |

| A2 | 845 |

| B | 1780 |

| C1 | 700 |

| C2 | 930 |

| D | 830 |

| E | 739 |

| F | 900 |

| G | 400 |

| H | 335 |

| I | 357 |

| J | 1595 |

| K | 473 |

| L | 404 |

| Kg. | 190 |

| Cv. III | 4 |

| Blade | 2.910 |

Characteristics:

♦ Bandsaw for the meat and fish industries. Special robustness for large meat processing facilities and easy operating procedure.

♦ The design eases a good integration on the different lines of cutting process.

♦ Robust 18/10 stainless steel construction.

♦ Stainless steel pulleys with double flap.

♦ Automatic process of tension control.

♦ Safety device to stop running blade in 4 seconds.

♦ On-off switch with emergency stop button, IP65.

♦ Safety device when opening door.

♦ No volt release system.

♦ Manufacturing of blade on the right and left hand side.

♦ Easy cleaning with water pressure.

♦ A one piece body construction to ease the better cleaning on a uniform platform.

♦ Detachable cleaners for easy cleaning, without the use of tools.

♦ Scrapers for pulley cleaning purpose on the cutting process.

| MODEL | BG-200 |

|---|---|

| ø Pulley | 200 |

| A1 | 345 |

| A2 | 605 |

| B | 925 |

| C1 | 320 |

| C2 | 475 |

| D | 520 |

| E | 385 |

| F | 300 |

| G | 180 |

| H | 175 |

| I | 195 |

| J | 210 |

| K | 325 |

| Kg. | 57 |

| CV./HP III II | 1 |

| Blade | 1.600 |

Characteristics:

♦ Robust 18/10 stainless steel construction.

♦ Construction to work in harsh environment with reliability.

♦ Automatic preset tension control.

♦ Easy cleaning with water pressure.

♦ Detachable cleaners for easy cleaning, without the use of tools.

♦ Protection index IP65.

♦ Machine conforms to Directive 98/37/EC.

| MODEL | BG-220 | BG-250 | BG-300 |

|---|---|---|---|

| ø Pulley | 220 | 250 | 300 |

| A1 | 390 | 400 | 400 |

| A2 | 695 | 740 | 740 |

| B | 935 | 1045 | 1195 |

| C1 | 350 | 400 | 450 |

| C2 | 560 | 600 | 650 |

| D | 610 | 660 | 660 |

| E | 430 | 480 | 530 |

| F | 385 | 420 | 470 |

| G | 220 | 270 | 320 |

| H | 195 | 225 | 275 |

| I | 215 | 250 | 250 |

| J | 235 | 255 | 255 |

| K | 395 | 410 | 410 |

| Kg. | 73 | 85 | 97 |

| CV./HP III II | 1 | 1,5 | 2 |

| Blade | 1740 | 1985 | 2340 |

Characteristics:

♦ Robust 18/10 stainless steel construction.

♦ Construction to work in harsh environment with reliability.

♦ Automatic preset tension control.

♦ Waste pan attached.

♦ Easy cleaning with water pressure.

♦ Detachable cleaners for easy cleaning, without the use of tools.

♦ Protection index IP65.

♦ Machine conforms to Directive 98/37/EC.

| MODEL | BGR-300 | BGR-360 | BGR-400 | BGR-450 |

|---|---|---|---|---|

| ø Pulley | 300 | 360 | 400 | 450 |

| A1 | 605 | 605 | 660 | 660 |

| A2 | 810 | 870 | 980 | 980 |

| B | 1.730 | 1.840 | 1.900 | 2010 |

| C1 | 610 | 700 | 740 | 810 |

| C2 | 860 | 1025 | 1.115 | 1.185 |

| D | 775 | 830 | 945 | 945 |

| E | 653 | 787 | 880 | 930 |

| F | 960 | 960 | 960 | 960 |

| G | 350 | 400 | 420 | 480 |

| H | 275 | 335 | 375 | 425 |

| I | 322 | 357 | 422 | 422 |

| J | 1.350 | 1.475 | 1.535 | 1.675 |

| K | 453 | 473 | 523 | 523 |

| L | 378 | 453 | 505 | 505 |

| Kg. | 210 | 250 | 270 | 305 |

| Cv. III | 3 | 4 | 4 | 5,5 |

| Blade | 2.500 | 2.910 | 3.155 | 3.500 |

Characteristics:

♦ Bandsaw for the meat and fish industries. Special robustness for large meat processing facilities and easy operating procedure.

♦ The design eases a good integration on the different lines of cutting process.

♦ Robust 18/10 stainless steel construction.

♦ Stainless steel pulleys with double flap.

♦ Automatic process of tension control.

♦ Safety device to stop running blade in 4 seconds.

♦ On-off switch with emergency stop button, IP65.

♦ Safety device when opening door.

♦ No volt release system.

♦ Manufacturing of blade on the right and left hand side.

♦ Easy cleaning with water pressure.

♦ A one piece body construction to ease the better cleaning on a uniform platform.

♦ Detachable cleaners for easy cleaning, without the use of tools.

♦ Scrapers for pulley cleaning purpose on the cutting process.

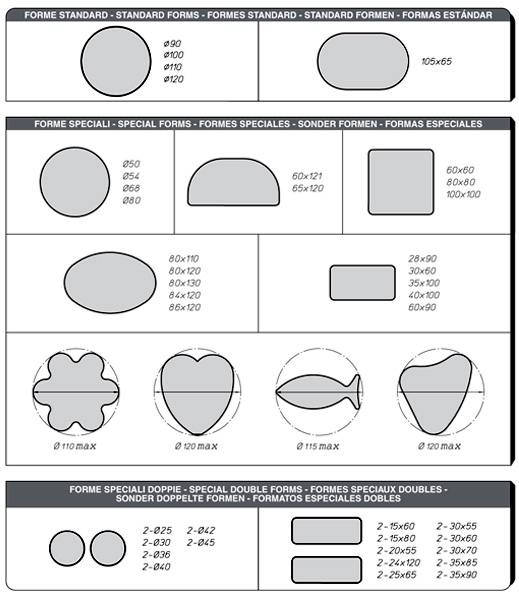

Specifications:

| Weight | Hamburger 4": 4.4 kg Hamburger 5": 4.8 kg Hamburger 6": 5.0 kg |

|---|---|

| Overall dimensions | Hamburger 4": A 70; B 305; C 255 Hamburger 5": A 85; B 320; C 270 Hamburger 6": A 95; B 330; C 280 |

| Bowl Dimension | Hamburger 4": mm 100 Hamburger 5": mm 130 Hamburger 6": mm 150 |

Key Features:

♦ Available in three models.

♦ Diameter 100 with meat press bowl and ejector made in stainless steel.

♦ Diameter 130 and 150 with meat press bowl made in anodized aluminium and ejector made in stainless steel.

♦ Container for cellophane incorporated and cellophane discs sampling.

♦ Syncronized working of compression and extraction of hamburger through a level control.

♦ Easy cleaning.

♦ Minimal servicing.

♦ In conformity with the international security and hygienic regulations.

♦ Optional: cellophane discs diameter 100 - 130 - 150.

Manual hamburger press entirely made from highly polished satin finished anodized aluminium.

Specifications:

| Capacity hopper | I | 23 |

|---|---|---|

| Productivity | RPH | 2100 |

| Engine Power | kW (HP) | 0,7 (1) |

| Net weight | kg | 50 |

Key Features:

♦ Strong production, efficiency and better organization

♦ AISI 304 stainless steel frame and anodized aluminum

♦ Showcase and transparent cover, removable and very robust in methacrylate. Hopper in stainless steel AISI 304, capacity 23 liters

♦ Forming rollers with interchangeable extruder polyethylene food

♦ Supplied with a standard roller and two scrapers: a tape for wire and red meat for white meat or fish.

♦ Easy to adjust the thickness to obtain the desired weight

♦ Conveyor

♦ Easy to disassemble for cleaning all parts in contact with the ground: bowl, blades, forming roller, conveyor. Materials for food contact

♦ Coded magnetic safety switches

♦ Electrical parts in boxes with IP 55 protection

♦ The machine complies with CE standards of hygiene and safety

Produce hamburgers, medallions, meatballs, sticks and special shapes. They can be fed with mixtures of red and white meat, even mixed with other ingredients: vegetables, olive oil, cheese, breadcrumbs ... Efficient, versatile, safe, reliable, compact, easy to maintain. For supermarkets, hypermarkets, collective catering services, meat processing, packaging centers, food industry.

Specifications:

| Dimensions | LT 7: mm 600x260x230 h;LT 14: mm 770x300x260 h |

|---|---|

| Net weight | LT 7: 19 kg;LT 14: 27 kg |

| Packaging dimensions | LT 7: mm 800x300x350 h;LT 14: mm 960x400x380 h |

| Capacity | LT 7: 7 lt.;LT 14: 14 lt |

| Gross Weight | LT 7: 24 kg;LT 14: 32 kg |

| Packaged Volume | LT 7: 0,09 metri cubi;LT 14: 0,115 metri cubi |

Exceptionally strong, very easy to be handled and operated, the two models by-hand sausage fillers, size 7-14 liters vertical, equipped with four funnels, are really the best for stuffing any kind of sausage.

The 18/8 aisi 304 stainless steel cylinder, the food approved aluminium piston with special finishing, the solid rack, the precision gears and the accurate manufacturing of all mechanicals details ensure a perfect working, the maximum efficiency and long life.

The sausage fillers have two gears and they are equipped with four changeable funnels for different kind of sausages.

Specifications:

| Capacity | l (kg) | 22 (19) |

|---|---|---|

| Three-phase motor | kW (HP) | 0,75 (1) |

| Single-phase motor | kW (HP) | 1,1 (1,5) |

| Net weight | kg | 120 |

Key Features:

♦ Body and cover stainless steel AISI 304

♦ Steel piston

♦ Cylinder polished stainless steel removable

♦ Mounted on two wheels

♦ Variable output speed

♦ Automatic start and stop controlled knee

♦ Piston return fast

♦ Three stainless steel funnels: ø 14, 20 and 30 mm

♦ Electrical Parts in IP56 box

♦ Machine conforming to EC rules on hygiene and safety

Powerful, robust and compact. Easy to operate in an ergonomic working position. Easy to clean. Strictest test of the surfaces. For butchers, meat, delicatessen, supermarket...

Specifications:

| Capacity | l (kg) | 32(27) |

|---|---|---|

| Three-phase motor | kW (HP) | 0,75 (1) |

| Single-phase motor | kW (HP) | 1,1 (1,5) |

| Net weight | kg | 130 |

Key Features:

♦ Body and cover stainless steel AISI 304

♦ Steel piston

♦ Cylinder polished stainless steel removable

♦ Mounted on two wheels

♦ Variable output speed

♦ Automatic start and stop controlled knee

♦ Piston return fast

♦ Three stainless steel funnels: ø 14, 20 and 30 mm

♦ Electrical Parts in IP56 box

♦ Machine conforming to EC rules on hygiene and safety

Powerful, robust and compact. Easy to operate in an ergonomic working position. Easy to clean. Strictest test of the surfaces. For butchers, meat, delicatessen, supermarket...

Specifications:

| Production | kg / h | 150/450 |

|---|---|---|

| Covers/Day | No. | 450 |

| Three-phase motor | kW (HP) | 0,75(1) |

| Single-phase motor | kW (HP) | 0,57(0.75) |

| N rpm disk | rpm | 320 |

| Net weight TF/MF | kg | 22(24) |

Key Features:

♦ Versatile and efficient: you can quickly make various types of work with an excellent finish

♦ Maximum hygiene: the components are made of materials suitable for contact with food, and are easily removable for quick cleaning

♦ Ventilated motor: powerful and quiet. It can perform all the work without effort

♦ NVR, low voltage (24 V)

♦ The machine complies with CE standards of hygiene and safety

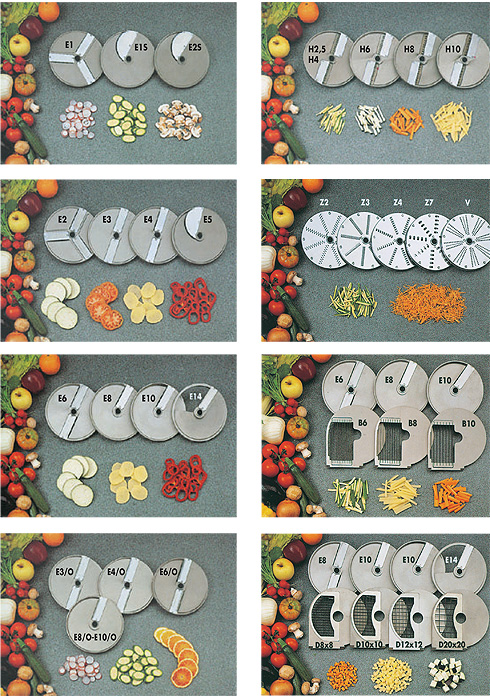

Cut into slices, cubes, sticks to fruit and vegetables. Ravel and diced mozzarella. Grated cheese, bread, nuts, chocolate. For restaurants, fast food, pizzerias, delis, caterers, supermarkets, laboratories, food preparation, ...

SLICING DISC "E" series, a blade stride.

Discs E1S and E2S to salami, mushrooms, cabbage, chicory

E5 Disc for tomatoes, lemons, oranges, apples, bananas, grapefruit, pineapple, ....

SLICING DISC "E" series, 1, 2 or 3 blades.

For potato chips, potatoes, turnips, cabbages, cucumbers, carrots, artichokes, onions, mushrooms, zucchini, eggplant, fennel, ...

Discs E1, E2, E3, E4, E6, E8. E10, E14 and special disks EC to match the disks B and D for "pommes frites" and dicing.

DISCS CORRUGATED series "E / O", 1 or 2 blades.

To obtain slices of fruit and vegetables of various thick wavy.

Hard E3 / O, E4 / O, E6 / O, E8 / O, E10 / O and special disks

EC / O to match the disks B and D for "pommes" frites and dicing.

CUTTING DISCS FOR MATCH "H" series.

For celery, zucchini, beets, bitter roots, carrots, potatoes, turnips, ....

Discs H2, 5x2, 5, H4x4, H6x6, H8x8, H10x10

GRATING AND RECORDS FOR SHREDDING series "ZV"

For carrots, celery, potatoes, turnips, beets, red cabbage, radishes, Swiss cheese, mozzarella, ...

Discs Z2, Z3, Z4, Z7

Disco "V" for cheese, bread, almonds, chocolate ..

BLADES FOR CUTTING STICK "B" series.

For fried potatoes, carrots, zucchini, ... Use in

Combined with a hard "EC" (EC6, EC8, EC10) sticks for 6x6, 8x8, 10x10 mm. Using a record number of EC / O you get sticks with two corrugated sides.

Discs b8x8, B10x10, B12x12, B20x20

DISCS DICING "D" series.

For soups, salads, salads, pickles, ....

Used in combination with a hard "EC" (EC8, EC10, EC14) for 8x8x8 cubes, 10x10x10, 12x12x14, 20x20x14 mm. Using a disc in the series EC / O cubes are obtained with two corrugated sides.

Discs D8x8, D10x10, D12x12, D20x20

For each disc, the figure following the letter indicates the height of cut in mm.

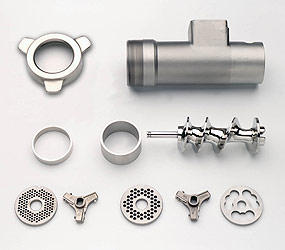

Specifications:

| Mouth | 32/98 | |

|---|---|---|

| Production | kg/h (kg/min) | 750 (12,5) |

| Three-phase motor | kW (HP) | 3(4) |

| Single-phase motor | kW (HP) | 2,2(3) |

| Weight TF/MF | kg | 74(77) |

Key Features:

♦ Outer mouth of stainless steel AISI 304:

♦ Enterprise: 1 plate and a stainless steel self-sharpening knife

♦ Unger: ø 98, 5 stainless steel pieces, with two rings

♦ Conveyor and pipe supply volume increased: increased flow from 50% to 80% compared to traditional meat grinder 32.

♦ Excellent grinding, due to the particular geometry and very tight tolerances between the propeller and mouth.

♦ Fixing mouth fast and robust

♦ Body and 304 stainless steel hopper

♦ Safe sanitation and simple: the mouth, hopper, tube and the grinding unit can be removed and be thoroughly washed without risk of damage to the machine

♦ Motor with forced ventilation for continuous use

♦ Forward, stop and reverse NVR low voltage (24V)

♦ Electrical parts in sealed box IP 56

♦ The machine complies with CE standards of hygiene and safety standards and specifications for the meat grinder

Specifications:

| Mouth | 32/98 | |

|---|---|---|

| Production | kg/h (kg/min) | 1500 |

| Engine Power | kW (HP) | 4(5,5) |

| Weight-phase | kg | 117 |

Key Features:

♦ Outer mouth of the new design, stainless steel, available in two versions:

♦ Enterprise system: a plate and a stainless steel knife autoffilante

♦ Unger System: 3 plates, 2 knives and 2 rings

♦ Large hopper and exterior stainless steel AISI 304 satin

♦ Hopper Size (1085x615x125 mm)

♦ Forward, stop and reverse NVR low voltage (24V)

♦ AISI 304 stainless steel legs with wheels

♦ Easy access to the electrical and mechanical parts for fast service

♦ Ventilated motor for continuous use.

♦ Plates and knives, industrial

♦ The machine complies with CE standards of hygiene and safety standards and specifications for the meat grinder

Specifications:

| Production | kg/h | 1800 |

|---|---|---|

| Engine Power | kW (HP) | 5,25(7) |

| Weight-phase | kg | 135 |

| Mouth | 42/130 |

Key Features:

♦ Outer mouth of a new concept, specially treated cast iron, available in two versions:

♦ Enterprise system: a plate and a stainless steel knife autoffilante

♦ Unger System: 3 plates, 2 knives and 2 rings

♦ Large hopper and exterior stainless steel AISI 304 satin

♦ Hopper Size (1085x615x125 mm)

♦ Forward, stop and reverse NVR low voltage (24V)

♦ AISI 304 stainless steel legs with wheels

♦ Easy access to the electrical and mechanical parts for fast service

♦ Ventilated motor for continuous use.

♦ Plates and knives, industrial

Specifications:

| Mouth | 32/98 | |

|---|---|---|

| Production | kg/h(kg/min) | 500(8,3) |

| Meat Grinder Motor | V 400 / 3 50Hz kW (HP) V 230 / 1 50Hz kW (HP) | 2,2(3) |

| Compressor | V 200-V 240 / 1 50Hz kW (HP) | 0.19 (0.253) GAS: R-134a |

| Production Hamburgers | units/h | ~500 |

| Net Weight | kg | 60 |

Key Features:

♦ Coating and AISI 304 stainless steel hopper

♦ Denomination:

♦ Enterprise: 1 plate and a stainless steel knife, self-sharpening

♦ Unger: ø 82, 3 pieces, ø 98, 5-piece stainless steel pieces, with two rings

♦ Cover and lens removed for cleaning

♦ Grinding and independent refrigeration

♦ Electrical parts in airtight container with a degree of protection IP56, NVR, low voltage (24V).

♦ The machine complies with CE standards of hygiene and safety standards and specifications for the meat grinder

Specifications:

| Mouth | 32/98 | |

|---|---|---|

| Production | kg/h (kg/min) | 750(12,5) |

| Three-phase motor | kW (HP) | 3(4) |

| Single-phase motor | kW (HP) | 2,2(3) |

| Net Weight TF/MF | kg | 58(61) |

Key Features:

♦ Outer mouth of stainless steel AISI 304:

♦ Enterprise: 1 plate and a stainless steel self-sharpening knife

♦ Conveyor and pipe supply volume increased: increased flow from 50% to 80% compared to traditional meat grinder 32.

♦ Excellent grinding, due to the particular geometry and very tight tolerances between the propeller and mouth.

♦ Fixing mouth fast and robust

♦ Hopper body and removable stainless steel AISI 304

♦ Safe sanitation and simple: the mouth, hopper, tube and the grinding unit can be removed and be thoroughly washed without risk of damage to the machine

♦ Forward, stop and reverse NVR low voltage (24V)

♦ Electrical parts in sealed box IP 56

♦ The machine complies with CE standards of hygiene and safety standards and specifications for the meat grinder

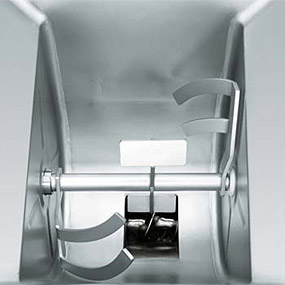

Specifications:

| Mouth | 32/98 | |

|---|---|---|

| Tank Capacity | | | 42 |

| Production | kg/h (kg/min) | 800 (13,3) |

| Power Mincer | kW (HP) | 2,2 (3) |

| Power Mixer | kW (HP) | 0,6(0,8) |

| Net Weight | kg | 100 |

Key Features:

♦ Mouth external large-scale production of 32/98 stainless steel AISI 304:

♦ Enterprise: 1 plate and 1 stainless steel self-sharpening knife

♦ Unger S5: ø 98, 3 plates, 2 knives and two self-sharpening stainless steel rings

♦ Private, group grinding blades and AISI 304 stainless steel tank

♦ Two independent motors with reverse (reverse)

♦ Transmission by silent and maintenance-free gear

♦ Group-grinding bowl and lid secured with safety microswitches

♦ Electrical parts in air-tight container with a degree of protection IP56.

♦ NVR controls with low voltage (24 V)

♦ Machine complies with EC hygiene and safety

Versatile and powerful. With the mixer function. For butchers, meat laboratories, supermarkets and community.

Specifications:

| Mouth | 32/98 | |

|---|---|---|

| Tank Capacity | | | 84 |

| Production | kg/h (kg/min) | 1200(20) |

| Power Mincer | kW (HP) | 3(4) |

| Power Mixer | kW (HP) | 1,1(1,5) |

| Net Weight | kg | 200 |

Key Features:

♦ Mouth external large-scale production of 32/98 stainless steel AISI 304:

♦ Enterprise: 1 plate and 1 stainless steel self-sharpening knife

♦ Unger S5: ø 98, 3 plates, 2 knives and two self-sharpening stainless steel rings

♦ Structure and cover in stainless steel AISI 304. Mouth, Group grinding blades and AISI 304 stainless steel tank, removable for easy cleaning. Mounted on wheels with brakes

♦ Two ventilated motors for continuous use: meat grinder blades and feeder / mixer. The two motors can work independently and are equipped with reverse (reverse)

♦ Transmission by silent and maintenance-free gear

♦ Easy access to electrical and mechanical parts for maintenance

♦ Group-grinding bowl and lid secured with safety microswitches

♦ Electrical parts in air-tight container with a degree of protection IP56.

♦ NVR controls with low voltage (24 V)

♦ Machine complies with EC hygiene and safety standards and specifications for the meat grinder.

Tub of 84 liters. Two independent motors, can also be used as a mixer. Versatile, powerful, efficient and secure. All stainless steel. For butchers, meat laboratories, supermarkets and community.

Specifications:

| Mouth | 32/98 | |

|---|---|---|

| Tank Capacity | | | 117 |

| Production | kg/h (kg/min) | 1.500(25) |

| Power Mincer | kW (HP) | 5,2(7) |

| Power Mixer | kW (HP) | 1,5(2) |

| Net Weight | kg | 266 |

Key Features:

♦ Private, group grinding blades and stainless steel tank 304. On stainless steel legs. Wheels with brakes

♦ Mouth external large-scale production of 32/98 stainless steel AISI 304:

♦ Enterprise: 1 plate and 1 stainless steel self-sharpening knife

♦ Unger S5: ø 98, 3 plates, 2 knives and two self-sharpening stainless steel rings

♦ Two independent motors for grinding and mixing the group, with reverse (reverse). Transmission using special gears in oil bath

♦ Group grinding, mouth, and bath blades easily removable for easy cleaning

♦ Electrical parts in air-tight container with a degree of protection IP56. NVR controls with low voltage (24 V)

♦ Machine complies with EC hygiene and safety standards and specifications for the meat grinder

Large capacity, powerful and versatile. With the mixer function. Laboratories for meat, supermarkets and hypermarkets, catering, industry, ...

Specifications:

| Blade Diameter | 300 mm |

|---|---|

| Cutting capacity | 210x210 - 230 - 260x210 |

| Dimensions | A 510, B 470, C 600, D 550, E 470, F 240, G 290; |

| Motor power | 0.30 hp |

| Weight | 32 kg |

Key Features:

♦ Slicer for restaurants.

♦ Sharpener built-in two days.

♦ Concave blade forged.

♦ Poly-v belt drive and automatic tensioner.

♦ Selection of cut from 0 to 25 mm with a cam mechanism driven by a graduated knob.

♦ Sliding bearings of the carriage cu.

♦ Components in contact with the product is completely removable for easy cleaning.

♦ Virtually maintenance.

♦ Conforms to European safety standards.

Slicer totally molten alloy of aluminum and titrated protected anodization

Specifications:

| Model | AM 250 | AM 300 | |

|---|---|---|---|

| Blade diameter | mm | 250 | 300 |

| Engine | kW (HP) | 0,22 (0,30) | 0,22 (0,30) |

| Carriage travel | mm | 290 | 290 |

| Cutter width | mm | 200 | 250 |

| Cutter width | mm | 190x260 | 210x260 |

| Cutting thickness | mm | 0/15 | 0/15 |

| Net weight | kg | 24 | 24.5 |

Key Features:

♦ Made of aluminum alloy treated by anodic oxidation.

♦ Poly V belt drive

♦ Built-in sharpener.

♦ Cart on a double ground bar.

♦ For the retail and catering.

♦ Answering Machines Directive 98/37/EEC.

♦ Commands with NVR

Specifications:

| Motor power | 500 Watts/ 230 V~ alternating or 400 V~ three-phase current |

|---|---|

| Blade (ømm) | 300mm |

| Cut lenght(mm) | 250mm |

| Cut height(mm) | 180mm |

| Slice thickness(mm) | 0,5-10 mm |

| Slicing speed | 30-70 strokes / min. |

| Interface | serial |

| Restraint length | 230 mm |

| Footprint | 540 x 440 mm |

| Exterior dimensions | 600 x 880 x 500 mm |

| Workspace | 700 x 900 x 640 mm |

| Blade speed | 229/min |

| Slices per minute max. | max. 70/min. |

| Operating period | Continuous duty |

| Emission noise level | < 69 dBA |

| Net weight | 69 kg |

Key Features:

♦ Made of aluminum alloy treated by anodic oxidation.

♦ Poly V belt drive

♦ Built-in sharpener.

♦ Cart on a double ground bar.

♦ For the retail and catering.

♦ Answering Machines Directive 98/37/EEC.

♦ Commands with NVR

Professional Benefits:

♦ Removable, 2-disc blade sharpener

♦ Robust cleaning brush

♦ Special oil

♦ Carriage for 230 mm restraint length

♦ Patented transport chain

♦ Patented slicing product advance

♦ Smooth, freely accessible surface everywhere in high-grade anodic design

♦ Low layout for ideal insertion of the slicing items on the carriage

♦ 500 Watt powerful motor with cooling system and double bearing supported gear

♦ Hard-Chromium plated, special high-performance blade Ø 300 mm with narrow blade sheath and closed blade cover plate

♦ Orderly, easliy accessible control terminal with drip-proof foil keyboard

♦ Smooth-running carriage with motorised feed of slicing product

♦ Freely controllable carriage stroke number fitting for every type of slicing items for 30-70 strokes / min.

♦ A Bluetooth interface facilitates fast, competent programming, taken care of by the GRAEF parent plant

♦ Many options for specific requirements